MENUMENU

MENUMENU

MENUMENU

Understanding your options in today’s combination sewer cleaner market can be daunting, let alone considering the possibility of a water recycling sewer cleaner. In the past few years, the market has seen an upward trend in the purchasing and utilization of water recyclers in place of traditional combination trucks. There are many reasons contractors and municipalities may choose a recycler. Most notable is the ability to work a full day utilizing one tank of water, eliminating time lost associated with debris dumping and refilling water tanks throughout the day. This vastly improves productivity and, in many cases, increases profit.

There are two options when purchasing a water recycler: add a recycling component to a traditional combination truck or buy a purpose-built water recycler. It is essential to understand what you are getting and to set your expectations accordingly. This article will reference Option A for the bolt-on system and Option B for the purpose-built system.

The bolt-on or add-on to a traditional combination sewer cleaner is similar to the addition of aftermarket accessories in the automotive industry that allows a product to do additional functions or perform outside of the intentional design for the vehicle.

The concept of providing the customer with additional features by adding a filter or series of filters to a traditional combination truck is excellent. The cost to the manufacturer is very low, and the cost to the customer is lower than that of a purpose-built recycling truck. However, there are definite drawbacks to this option. In the field, users comment that bolt-on recyclers are ineffective in removing grease or fine silts, as the filters used become blinded and easily clogged with material. Time spent in the field has proven that most sewer systems contain lines with grease and/or silt.

Let us consider this option, ignoring the grease filtration issue. If no grease exists, what is the smallest solid that a bolt-on recycling component can filter? What is the PPM (parts per million) of solids in the system that remain after the filtration process is complete?

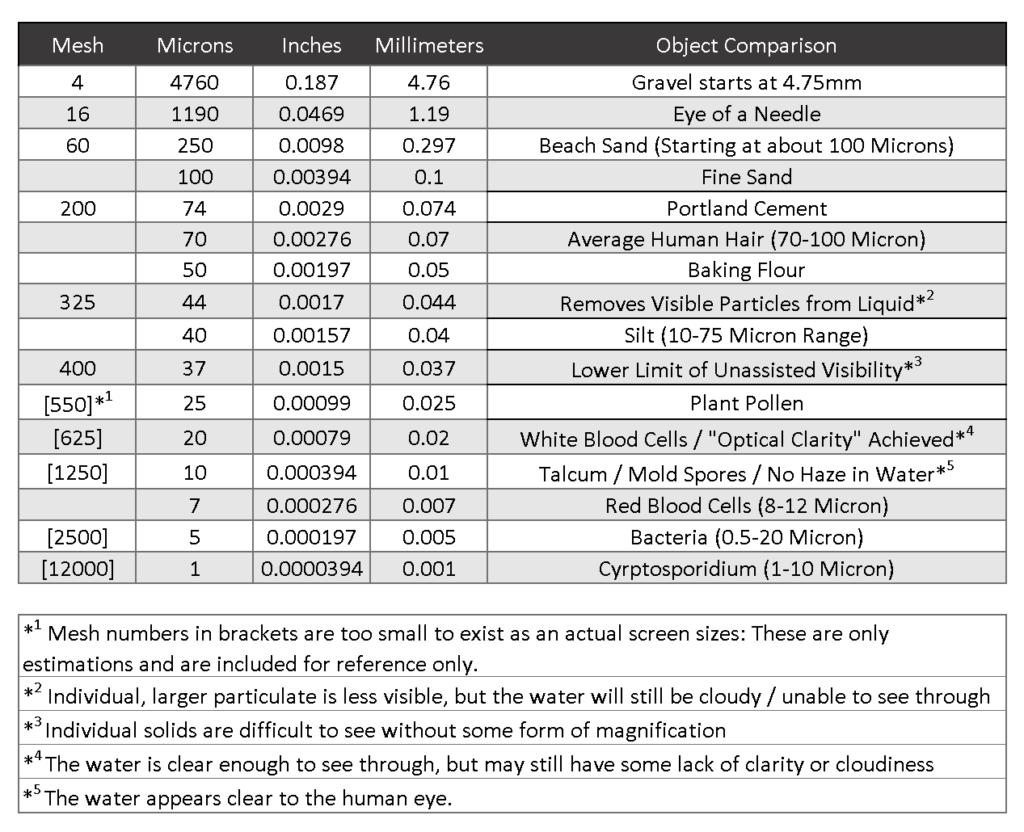

Most bolt-on systems try to filter down to 100 microns (the consistency of fine beach sand – see reference chart). Well, that isn’t that bad, right? Fine grains of sand are pretty small, yes. However, given the large volume of recycled water, you must consider the PPM of material going through the system. Even a moderate quantity of sand-size material can be very detrimental to parts and components downstream of the filtration system, such as high-pressure pumps, plumbing, hoses, and nozzles. Most standard combination vac trucks aren’t designed to handle the number of solids that can pass the filtration system with add-on recycling attachments. Users in the field have had new nozzles destroyed within days of use on a truck with a bolt-on recycler but were originally proudly touting their trucks’ ability to filter down to 100 microns.

Overall, the consensus on most bolt-on recycling attachments is that, while it’s cheaper than buying a purpose-built unit, constantly replacing filters and the wear and tear these systems put on their machines leads to a higher upkeep cost than most customers might realize. That said, some bolt-on options can produce higher-quality recycled water than some lower-end purpose-built machines. Again, being informed and understanding what you are getting and what to expect is essential.

It is true… Purpose-built water recyclers usually come with a higher purchase price. This is largely due to the added development costs and quality components used in manufacturing. On the upside, you get what you pay for; the components are more reliable, resistant to corrosion and decomposition, and specifically chosen for their ability to be used long-term with recycled water.

Additionally, purpose-built recycling units recycle water more efficiently than their bolt-on counterparts. These units are engineered with the capability to recycle at a quicker rate with a lower solid size, as well as lower PPM. This means less wear on the machine and longer service life than a traditional combination sewer cleaner truck with an add-on filtration system.

There are two schools of thought regarding purpose-built water recycler units: active and passive. Active filtration involves using replaceable filters to actively separate fats, oils, grease, and other solids from the water. Passive separation primarily uses gravity (like settling tanks) or centrifugal forces (most commonly seen in filtration cyclones) to filter the water instead of replaceable filters. In a well-engineered machine, active and passive filtration are equally effective, and many recycler systems utilize both filtration and separation in their design. However, as we mentioned previously, any system using mesh filters will generally have issues with grease and silt, which adds to upkeep and maintenance costs.

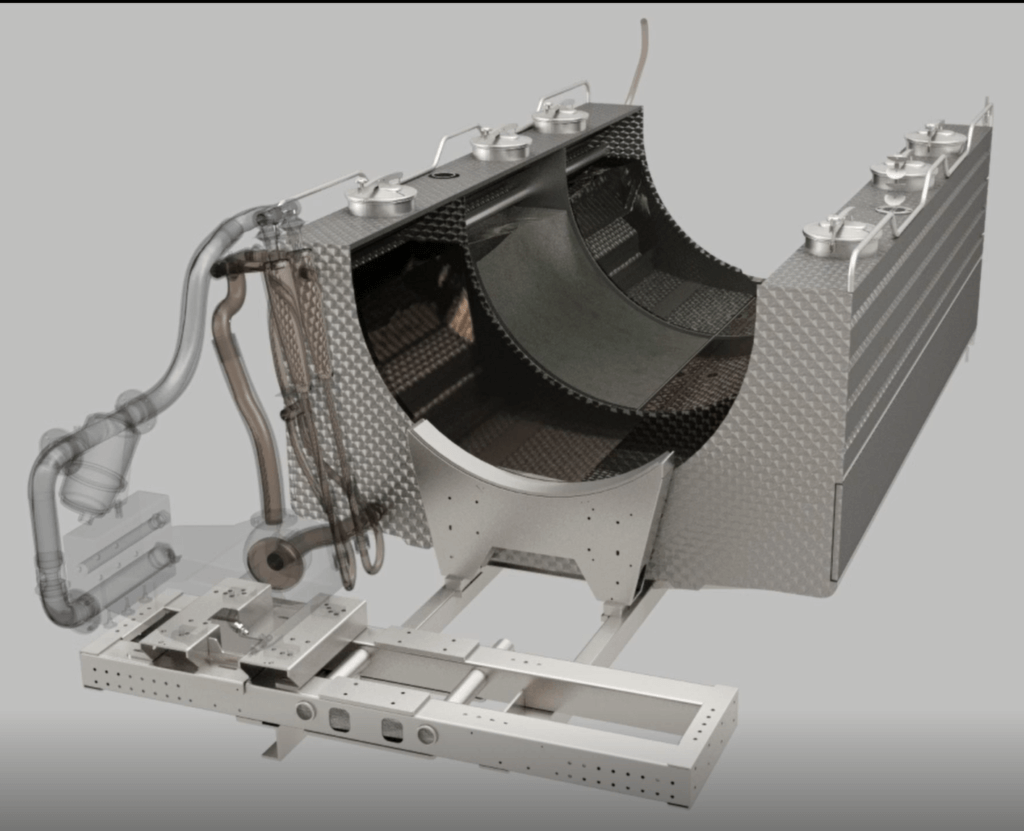

The GENESIS Recycler from Cappellotto by Sewer Equipment separates solids down to a sub-50 micron size while recycling water at a rate of up to 300 gallons per minute. 50 micron is the consistency of flour, is finer than human hair, and barely larger than pollen. Unlike beach sand, the recycled material from a purpose-built unit is not abrasive and largely decreases the possibility of causing damage to downstream components. The GENESIS uses a passive separation approach, which slows the water and allows the natural separation of solids. This unique and effective separation process, combined with centrifugal cyclones, makes it possible for purpose-built recyclers to break down solids to such a small consistency.

There are “purpose-built” recyclers on the market today that only filter or separate down to 100, 300, and 500 microns, as some manufacturers have opted to lower their separation capabilities to increase recycling capabilities. The GENESIS has focused on consistent improvement and innovation to maintain the quality and quantity of water and is not willing to sacrifice either.

If you are in the market for a combination sewer cleaner and are considering a water recycler to increase efficiencies and significantly decrease the time spent on dumping and filling, be sure you understand what option is best for your business. Ask the hard questions of your salesperson and make sure you know what you are getting and what to expect from your unit in the future.

Author Notes: Guy Leslie is the Product Specialist for the Genesis Water Recycler from Cappellotto by Sewer Equipment. He has 12 years of experience in the sewer cleaning industry, primarily in product support and sales. Guy has served on the NASSCO Board of Directors, involved with several NASSCO committees, and was most recently the Chair of the RehabZone Committee.